In the ever-evolving world of caravan manufacturing, Regent Caravans, a pioneer in the industry, has been making waves with their innovative construction methods. I recently had the opportunity to sit down with Andrew Crank, the CEO of New Gonow Group, which manufactures Regent, Snowy River, and Newgen Caravans, to discuss the company’s revolutionary Alopex construction method.

Andrew Crank, a seasoned professional with a wealth of experience in the Manufacturing and Construction industries, holds a Civil & Mechanical Engineering Degree from RMIT University. His extensive knowledge and understanding of material strength and selection underscore his expertise in building robust & cost-effective structures in the automotive & caravan industries.

Before his current role, Crank served as the Manager of the Motorhomes Division at Jayco Corporation Pty Ltd (Australia). Prior to that, he was a Director at Actco-Pickering Metal Industries Pty Ltd for nearly 18 years, where he held various roles including Director of Projects, Director of Operations, and Director of Design & Development. He also had a stint as the General Manager at Pioneer Campers for close to six years.

“The caravan industry is witnessing a paradigm shift in construction methods, with Regent Caravans at the forefront of this revolution, The company’s innovative Alopex construction method is setting new standards in the industry, promising a future of durable, efficient, and sustainable caravans” says Crank

A Brief Company History

Regent Caravans was founded in Melbourne in 1991, born from a humble family operation with a love for travel. Over the years, the company has helped thousands of Australians create unforgettable holiday experiences with their range of luxury caravans. In 2015, the company was acquired by the New Gonow Group, a large company with a global reputation for caravan and motorhome design and build quality. This acquisition led to the introduction of state-of-the-art manufacturing processes and the development of the Alopex construction method.

“Regent Caravans has always been about pushing boundaries and setting new standards,” Crank shared.

The History of Using Wood for Caravans

The caravan industry, for a long time, relied heavily on timber for construction. “Wood was the go-to material for caravan frames,” Crank explained. “It was readily available and easy to work with.” However, as the industry evolved, the drawbacks of timber, such as its susceptibility to moisture, decay, and insects, became increasingly apparent, leading to a shift in construction materials.

Wood vs Aluminum Composite

The debate between wood and aluminum composite in caravan construction is a tale of tradition versus innovation. “While wood has its merits, it falls short in durability and strength,” Crank pointed out. “Aluminum, on the other hand, offers resistance to moisture, decay, and insects, making it a superior choice for caravan construction.”

Different construction methods come with their unique set of advantages and disadvantages. Traditional stick and staple methods, while cost-effective, do not offer the same level of durability as aluminum frame construction. Aluminum frame methods, particularly the Alopex construction method, provide a higher degree of strength and longevity.

In tropical regions, where humidity levels are high, timber frames are prone to rotting. “Wood has little resistance to moisture, making it less suitable for these areas,” Crank explained. “Aluminum, with its resistance to moisture, is a more viable option for caravan frames in such regions.”

Alopex & The Future of Caravan Manufacturing in Australia

The future of caravan manufacturing in Australia is looking bright, with more manufacturers adopting innovative construction methods.

“The industry is moving towards more sustainable and durable construction materials,” Crank shared. “At Regent Caravans, we are leading the way with our Alopex construction method.”

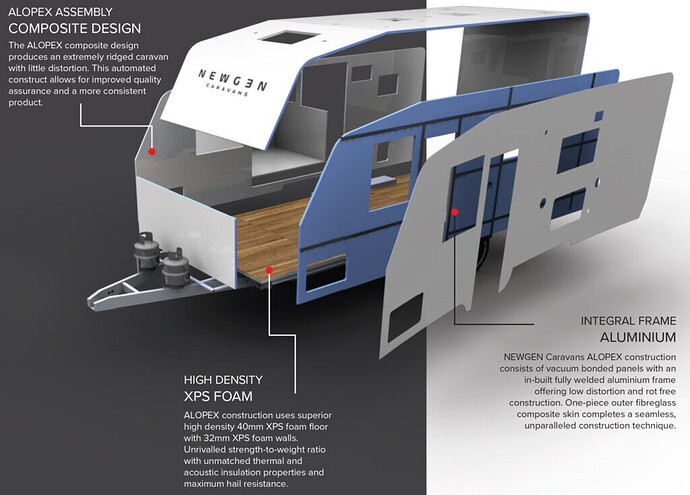

The Alopex construction method, developed by Regent Caravans, offers numerous benefits to consumers

- Uses aluminum and XPS foam to construct robust and lightweight caravan walls and floors. “With a superior density of 40mm XPS foam for floors and 32mm for walls, Alopex ensures a fully insulated structure, leaving no air gaps. This results in superior insulation, ensuring a comfortable interior regardless of the weather conditions.” Says Crank

- The strength-to-weight ratio is unrivaled, leading to lighter caravans, which can result in better fuel efficiency.

- Increased durability reduces the risk of insect infestation and decay.

- High level of resistance and protection from hail damage.

- When these panels are mass-produced, the cost is much lower & the quality control process is more consistent & controllable making Alopex a cost-effective solution that is revolutionizing caravan construction

Regent Caravans has received numerous accolades for its innovative approach to caravan manufacturing.

“We were awarded the Caravan Industry Victoria’s Manufacturer of the Year in 2017 and 2018,” Crank proudly shared. “These awards are a testament to our commitment to innovation and quality.”

The shift towards aluminum and composite materials is not exclusive to Regent Caravans. Many other Australian manufacturers are also moving in this direction. “The industry is recognizing the benefits of these materials,” Crank noted. “It’s a positive trend that bodes well for the future of caravan manufacturing in Australia.”

Having had the opportunity to converse with Andrew Crank, it is clear that the future of caravan manufacturing lies in innovative construction methods like Alopex. As a passionate caravan enthusiast & technologist, it is exciting to witness this shift towards more durable and sustainable materials that will redefine the caravan industry, not just in Australia, but globally.

The caravan industry is on the cusp of a revolution, with companies like Regent Caravans leading the way. The shift from traditional timber frames to more durable and sustainable materials like aluminum and composite materials is a testament to the industry’s commitment to innovation and sustainability. As we move forward, we can expect to see more high-quality, innovative, and durable caravans on the market.